I. Okwu Mmalite nke Desulfurization Absorber

Isi ọrụ nke desulfurization absorber bụ ikesa na fesa slurry gwakọtara na limestone na gypsum site mgbasa mgbapụta, na ịgba oyi akwa pipelines banye sọlfọ dioxide na flue gas na-abanye na absorber. sọlfọ dioxide nke slurry na-etinye n'ime ya na-emeghachi omume na nkume nzu na ikuku oxygen na-adaba n'ime ihe ntinye iji mepụta calcium sulfate dihydrate (gypsum), mgbe ahụ, gypsum nke a na-emepụta na-ahapụ ya na usoro mmiri mmiri gypsum site na mgbapụta mgbapụta gypsum maka akpịrị ịkpọ nkụ.

II. Mpaghara atọ na-arụ ọrụ nke Absorber desulfurization

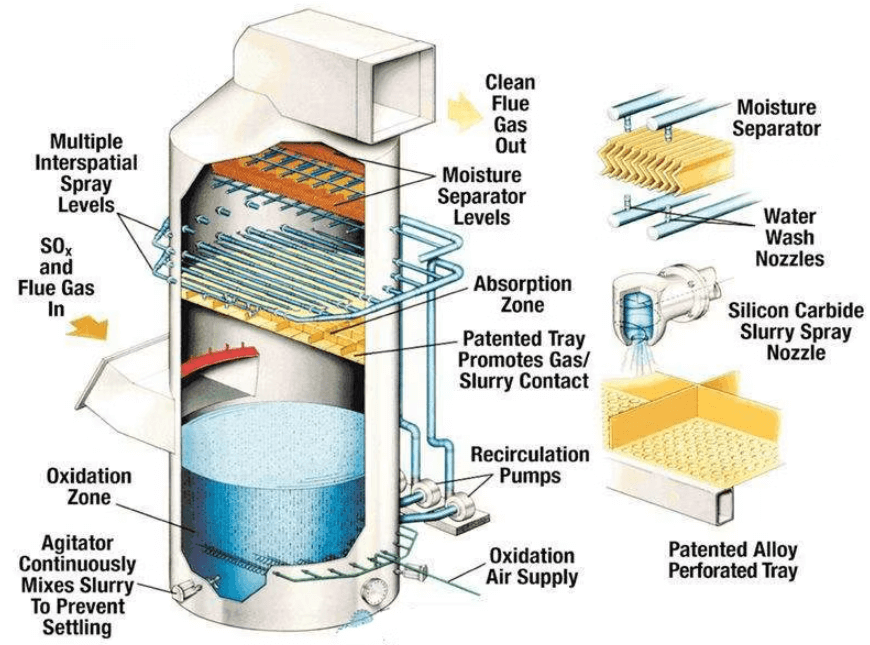

Enwere ike kewaa ihe ntinye ahụ n'ime mpaghara atọ na-arụ ọrụ site n'elu ruo na ala: oxidation crystallization, absorption and demisting zone.

(1) Oxidation crystallization zone na-ezo aka na slurry ọdọ mmiri nke absorber, na isi ọrụ bụ igbari limestone na oxidize calcium sulfite.

(2) Mpaghara absorption gụnyere ntinye ihe ntinye, tray na ọtụtụ n'ígwé nke sprays. E nwere ọtụtụ oghere cone nozzles na nke ọ bụla oyi akwa nke ịgba ngwaọrụ; isi ọrụ nke absorber dabere na acidic mmetọ na ofufe ash absorption na flue gas.

(3) Mpaghara mbibi na-egosipụta demisters okpukpu abụọ n'elu oyi akwa ịgba. Isi ọrụ ya bụ ikewapụ ụmụ irighiri mmiri na gas flue, na-ebelata mmetụta na akụrụngwa nke ala na usoro onunu ogwu.

Ebe a na-etinye ihe na-ekpuchi ihe na-ezo aka na mpaghara n'etiti etiti etiti nke ntinye nke ntinye na nke kachasị elu nke oyi akwa. Slurry a na-efesa na-asachapụ gas flue nwere sọlfọ dị na mpaghara a. Ogologo zuru oke nke mpaghara absorption na-eme ka ọnụọgụ desulfurization dị elu. Nke dị elu dị elu, na-ebelata ọnụego mgbapụta mgbapụta achọrọ n'okpuru otu ihe achọrọ na ọnụego desulfurization.

A kọwapụtara mpaghara ịgba mmiri nke absorber dị ka:

(1) Ụlọ elu na-efesa: 1.5m n'okpuru nozzle kacha ala ruo ebe mpụta nke nozzle kacha elu.

(2) Ụlọ elu kọlụm mmiri: site na ntinye nke nozzle kacha nta ruo 0.5m n'elu kọlụm mmiri kachasị elu mgbe nfuli mgbasa ozi niile na-agba ọsọ.

The absorber bụ isi ngwaọrụ nke flue gas desulfurization usoro. Ọ na-achọ nnukwu mpaghara kọntaktị mmiri mmiri gas, ezigbo mmeghachi omume absorption gas, obere mfu nrụgide. Ọ dabara maka ọgwụgwọ flue gas nwere nnukwu ike. Emechara usoro usoro izizi ndị a na ngwaọrụ a:

① Absorption nke na-emerụ gas na-asa slurry;

② nkewa nke flue gas na ịsa slurry;

③ Neutralization nke slurry;

④ Oxidation nke etiti neutralization ngwaahịa n'ime gypsum;

⑤ Gypsum crystallization.

III. Ihe mejupụtara absorber

A na-ekekarị onye na-etinye ihe n'ime cylinder, ihe ntinye gas na ikuku gas na nhazi. The flue gas ntinye na ntinye na-edina n'etiti absorber na n'elu nke absorber kwekọrọ ekwekọ na-ahụkarị. The absorber cylinder nwere ike kewaa n'ime a slurry ọdọ mmiri, a ịgba oyi akwa na a demisting ebe na-arụ ọrụ. The slurry ọdọ mmiri dị na ala akụkụ nke absorber ntinye n'ozuzu, na ịgba oyi akwa na demister dị n'etiti flue gas ntinye na ntinye. The flue gas ntinye nke absorber nwere ike ịbụ n'elu kpọmkwem oghere ma ọ bụ a kehoraizin n'akụkụ oghere.

Ebe ịgba mmiri a na-ahụkarị na-egosi akwa akwa na nozzles na ngwaọrụ ndị ọzọ. Dabere na desulfurization usoro, a ga-akwadebe ebe ịgba mmiri nke ụfọdụ ndị na-etinye ihe na trays, mkpanaka Venturi na ngwaọrụ ndị ọzọ.

IV. Nhazi chọrọ maka Absorber

(1) Calcium-sulfur ruru ekwesịghị ịbụ ihe karịrị 1.05.

(2) Mgbe ị na-eji demister ụlọ elu, ọkụ ọkụ ọkụ ọkụ nke onye na-etinye ihe n'okpuru ọnọdụ imewe ekwesịghị gafere 3.8m / s, nke enwere ike nyochaa ya site na Coriolisfalazutereer.

(3) A na-ahọrọ usoro nhazi nke ọdọ mmiri slurry na ụlọ elu ahụ.

(4) Oge obibi nke mgbasa ozi slurry ekwesịghị ịbụ ihe na-erughị 4 min, na ụlọ elu kọlụm mmiri kwesịrị ịbụ ihe na-erughị 2.5 min.

(5) A ga-etinye mgbanaka na-ekpuchi mmiri na mkpuchi mmiri ozuzo na nkwụsịtụ nke flue ntinye ntinye na mgbidi kwụ ọtọ nke onye na-ekpuchi ya.

(6) Ekwesịrị ịhazi flue mgbaba nke ụlọ elu na-efe efe na-enweghị ihe ọ bụla n'ụzọ ntinye nke gbadara agbadata. Mgbe a nakweere nhazi ntinye kehoraizin, ekwesịrị ijide n'aka na ebe kachasị ala nke flue dị na ikpere aka mbụ dị n'akụkụ ntinye ihe ntinye bụ 1.5 ruo 2m dị elu karịa ọkwa mmiri na-arụ ọrụ nkịtị nke ọdọ mmiri absorber slurry. Enwere ike ịhazi flue mgbaba nke ụlọ elu kọlụm mmiri n'ụdị ntinye kwụ ọtọ ma ọ bụ kwụ ọtọ.

(7) Ebe dị anya n'etiti n'akụkụ ebe ịgbasa n'akụkụ nke ụlọ elu na-efe efe ekwesịghị ịbụ ihe na-erughị 1.8m.

(8) N'elu akwa akwa akwa nke ụlọ elu na-adịghị efu kwesịrị ịgbada ala, ebe net dị anya site na oyi akwa kacha ala nke demister ekwesịghị ịbụ ihe na-erughị 2m.

(9) Maka ụlọ elu ndị na-agba mmiri nke nwere trays porous na tabulators, trays porous na tabulator agụba kwesịrị ịbụ ihe alloy na-egbochi corrosion.

(10) Mgbe iyuzucha gas kpo oku na okpomọkụ mgbanwe ngwaọrụ adịghị arụnyere, nhọrọ nke imewe parameters dị ka efu ụlọ elu eruba ọnụego, mmiri mmiri-gas ruru, na slurry siri ike ọdịnaya nke absorber kwesịrị iburu n'uche ihe ndị chọrọ nke desulfurization arụmọrụ na mmetụta nke ihe ndị dị ka ibelata ego nke net flue gas ụmụ irighiri mmiri na-ebu.

(11) Ekwesịrị ịmegharị nhazi nke onye na-etinye ihe na-eme ka ọ bụrụ usoro nhazi nke ibu ọkụ ọkụ na ọdịnaya sọlfọ coal. Onye nwere ọgụgụ isina-abụghị ngwá agha nukliaslurry njupụta metersiLonnmeterA na-atụ aro ka nyochaa njupụta nke limestone na gypsum n'ọnụ ụzọ ahụ iji kwe nkwa ntọhapụ zuru oke.

Oge nzipu: Feb-05-2025